Grid Structure System

OverviewGird structure is constituted by pipe, tube and steel section welded. It

Overview

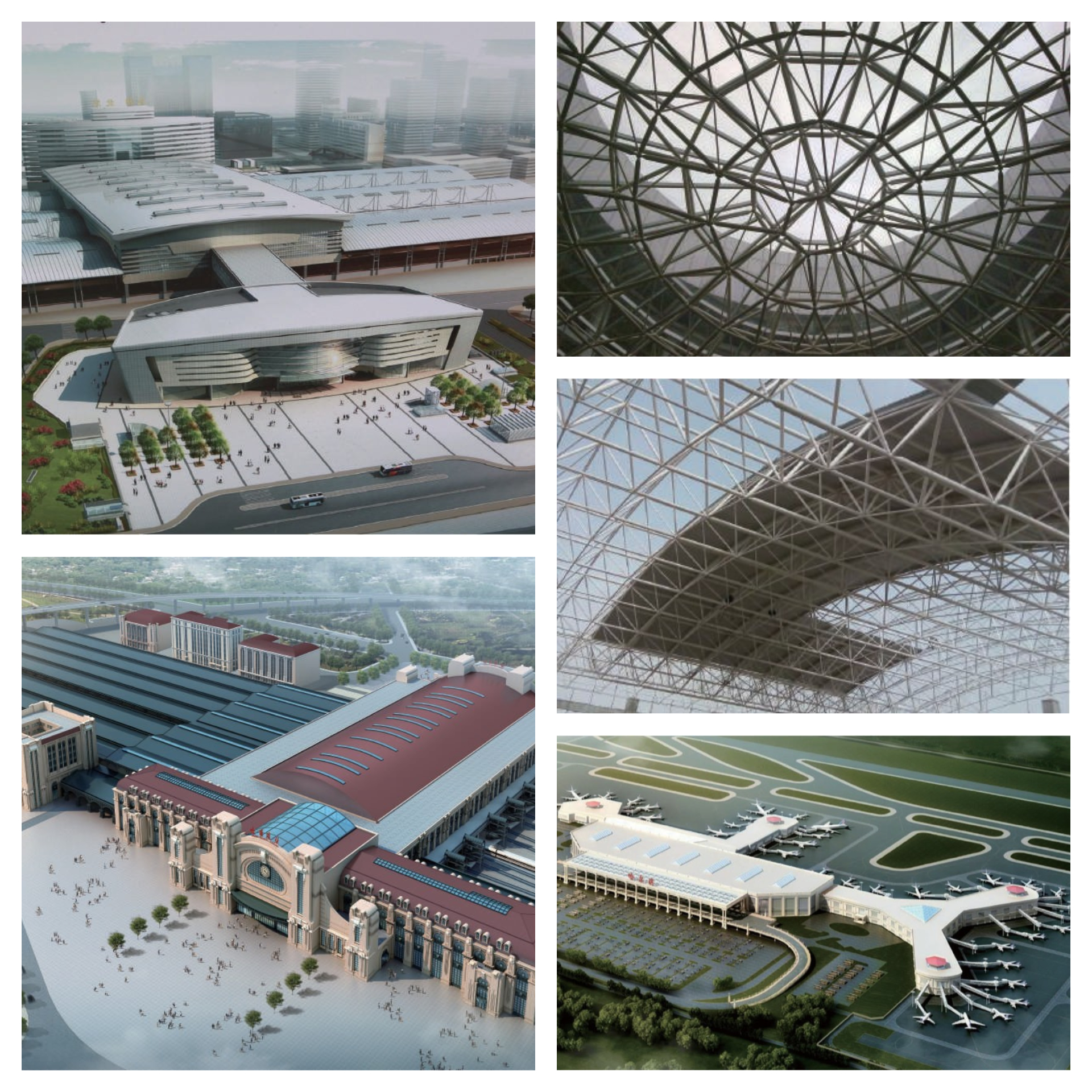

Gird structure is constituted by pipe, tube and steel section welded. It's suitable to big span buildings, like airports, storages, stadiums, stations, etc. The gird structure can span 150m.

Efficient Use of Space: The open-grid design of these structures allows for efficient utilization of interior space, making them ideal for large-scale applications.

Grid structures are commonly used in the construction of:

Arenas and Stadiums: Providing large open spaces for sporting events, concerts, and other gatherings.

Exhibition Halls and Convention Centers: Offering flexible layouts for trade shows, exhibitions, and conferences.

Industrial Facilities: Including warehouses, manufacturing plants, and distribution centers requiring expansive interior spaces.

Transportation Infrastructure: Such as aircraft hangars, railway stations, and terminals.

Features of WZH's Fabrication

Typcal Specifications

| Use | Hot Rolled / Built-up H-shapes Steel Columns, Steel Beams, Steel Rafter, Crane Beams, etc. |

| Scope of Work | Fabricate structural steel framing according to the structure drawings. |

| Work Description | Structural steel members complete, with cutting, welding, grit blasting, priming and painting, including all necessary fixing accessories such as stiffeners as specified. |

| Materials | Hot Rolled H Section/ I Section (UB, UC) / Steel Plates |

| Steel Grade | Q355B / Q235C |

| Surface Preparation | By Sand Blasting to SA 2½ DIN EN ISO 12944 T4 standard |

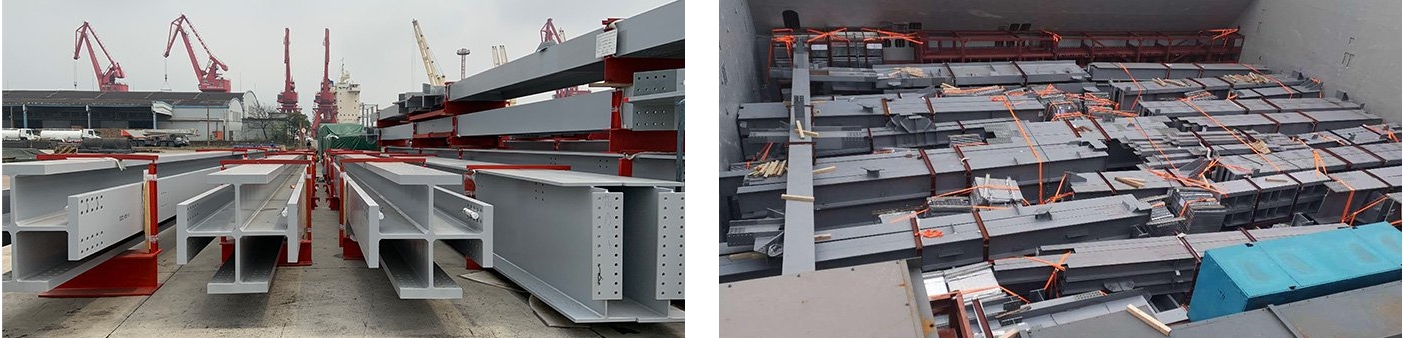

| Priming and Painting | 1 coat of zinc rich primer (60-80 microns) + 1 coat of epoxy-zinc finish paint (60-80 microns), Gray Color. |

| Notes: | All the specifications can be customized. |

| Capacity | 80000 Ton Structural Steel Fabrication Annually, Max thickness 100 mm. |

The grid structure system, also known as the grid shell structure, in steel construction is an assembly of interlocking steel beams and columns that form a three-dimensional structure. It exhibits a high degree of geometrical regularity or irregularity and is often used in large-span enclosures, such as sports arenas, exhibition halls, and aircraft hangars.

Key characteristics of grid structure systems include:

Large Span Capabilities: Due to the rigidity of the interconnected beams and columns, grid structures can span large areas without the need for internal support, creating extensive open spaces beneath.

Aesthetic Appeal: The geometric nature of the grid creates an appealing visual that is often left exposed in architectural designs for its high-tech industrial look.

High Strength to Weight Ratio: Steel construction allows for strong structures with less material, making grid systems surprisingly lightweight relative to their size and capacity.

Modularity: Grid structures are often modular, meaning they can be pre-assembled in various shapes and sizes and then transported to the construction site for installation, making them adaptable and efficient to construct.

Versatility in Design: The grid can flexibly conform to different shapes, including flat slabs or curved surfaces, opening up numerous design possibilities.

Excellent Load Distribution: The grid system evenly distributes load due to its bidirectional layout, which can be advantageous for buildings subject to uneven or dynamic loading.

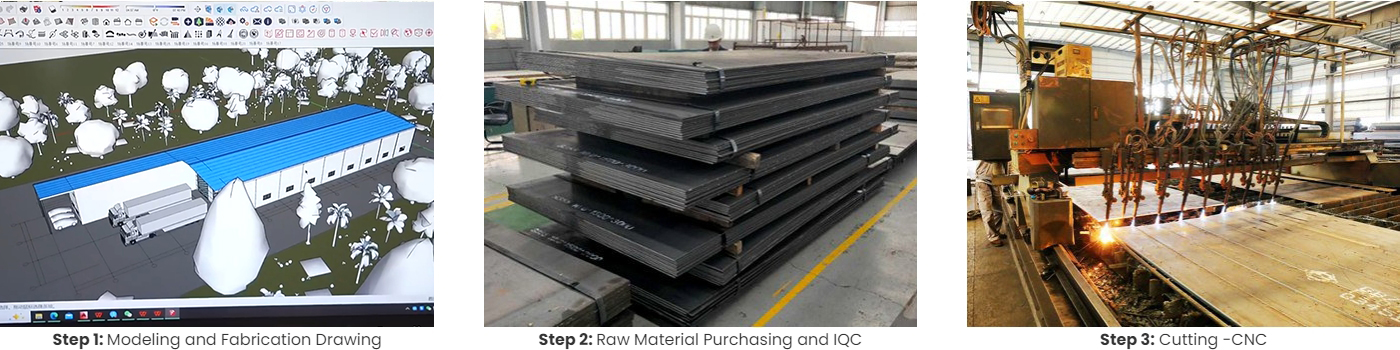

Typcal Fabrication Process of Plate Welded Steel Beams and Columns

Packing for Container Shipment and Bulk Shipment

FAQ

1.Q: Are your manufacturer or trading company?

A: We are manufacturer, we are group company with over 24 years experiences.

2. How to buy your ideal products?

A: 30% deposit before producing, 70% balance before loading.

3.Q: What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 30 to 40 working days.

4.Q:How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

5.Q:How to install after the goods arriving destination?

A: We will provide detailed shop drawings to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

Write Us

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're

creatingwould like to partner up or just say hi!