Steel Strucutre Bridge System

OverviewSteel is widely used around the world for the construction of bridges.It

Overview

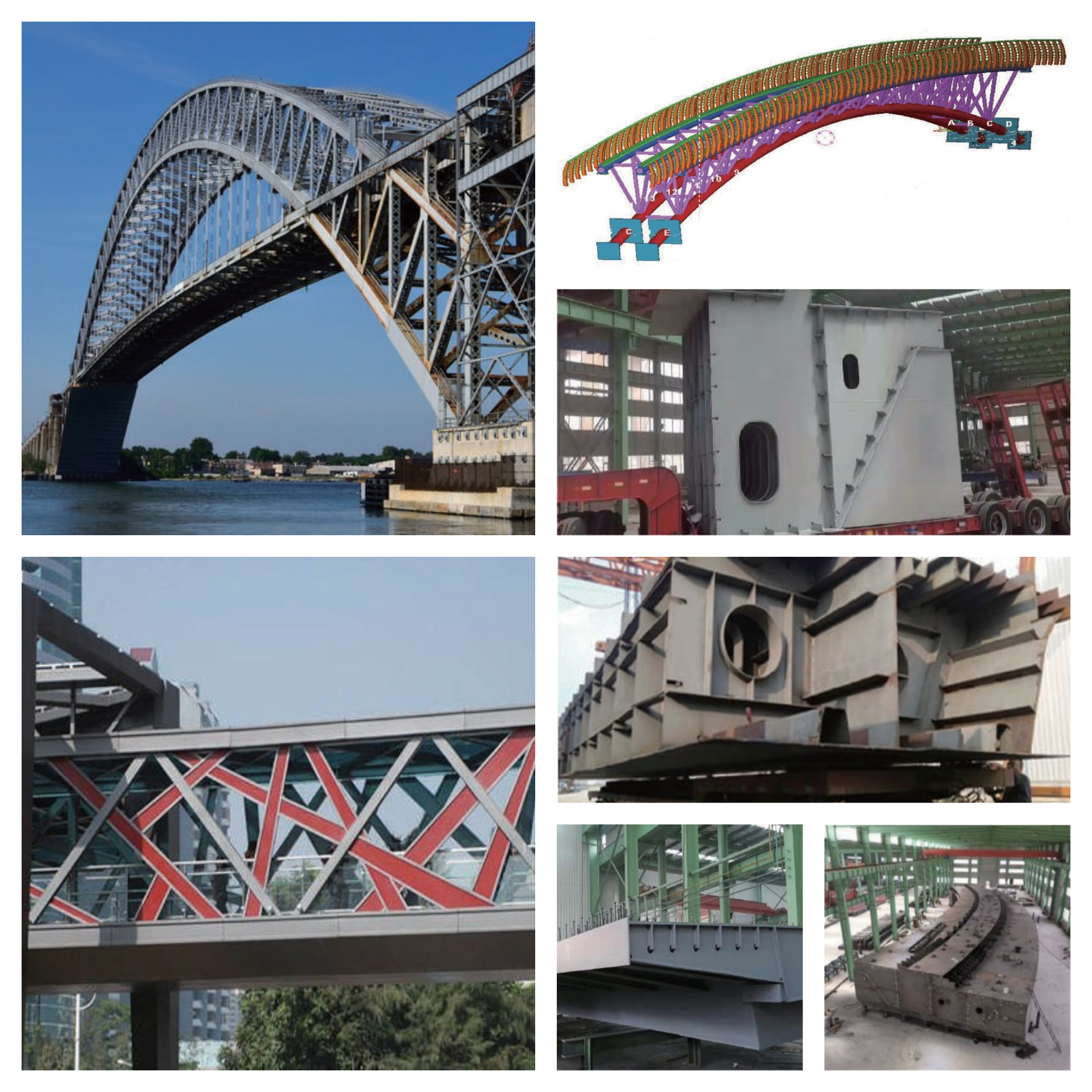

Steel is widely used around the world for the construction of bridges.It is a versatile and effective material that provides efficient and sustainable solutions. Steel has long been recognized as the economic option for a range of bridges. It dominates the markets for long span bridges, railway bridges, footbridges, and medium span highway bridges.

Composition:The Steel Structure Bridge System typically consists of steel beams, girders, columns, and trusses, all interconnected to form a robust and stable bridge structure. Additional elements such as decking, guardrails, and bearings may also be incorporated depending on the specific design requirements.

Features of WZH's Fabrication

Characteristics

Durability: Steel is known for its exceptional durability, capable of withstanding harsh environmental conditions including heavy loads, extreme temperatures, and corrosion.

Strength: Steel boasts high tensile strength, allowing for the construction of bridges capable of supporting heavy traffic loads without significant deformation or structural failure.

Versatility: Steel's versatility enables engineers to design bridges of various spans and configurations to suit different transportation needs and site conditions.

Sustainability: Steel is a sustainable construction material, as it is recyclable and offers a long service life, reducing the need for frequent maintenance and replacement.

Classifications:The Steel Structure Bridge System can be classified based on several criteria, including span length, intended use, and structural configuration. Common classifications include long span bridges, railway bridges, footbridges, and medium span highway bridges.

Typcal Specifications

| Use | Hot Rolled / Built-up H-shapes Steel Columns, Steel Beams, Steel Rafter, Crane Beams, etc. |

| Scope of Work | Fabricate structural steel framing according to the structure drawings. |

| Work Description | Structural steel members complete, with cutting, welding, grit blasting, priming and painting, including all necessary fixing accessories such as stiffeners as specified. |

| Materials | Hot Rolled H Section/ I Section (UB, UC) / Steel Plates |

| Steel Grade | Q355B / Q235C |

| Surface Preparation | By Sand Blasting to SA 2½ DIN EN ISO 12944 T4 standard |

| Priming and Painting | 1 coat of zinc rich primer (60-80 microns) + 1 coat of epoxy-zinc finish paint (60-80 microns), Gray Color. |

| Notes: | All the specifications can be customized. |

| Capacity | 80000 Ton Structural Steel Fabrication Annually, Max thickness 100 mm. |

Long Span Bridges: Ideal for spanning large distances, long span steel bridges are often used to cross rivers, valleys, and other obstacles where conventional construction methods are impractical.

Railway Bridges: Steel bridges provide essential crossings for railways, ensuring safe and efficient transportation of trains and freight over rivers, highways, and other obstacles.

Footbridges: Steel footbridges offer pedestrian access across rivers, parks, and urban areas, enhancing connectivity and promoting active transportation.

Medium Span Highway Bridges: Steel bridges are commonly employed in the construction of medium span highway bridges, providing vital links in transportation networks and facilitating the movement of vehicles and goods.

Typcal Fabrication Process of Plate Welded Steel Beams and Columns

Packing for Container Shipment and Bulk Shipment

FAQ

1.Q: Are your manufacturer or trading company?

A: We are manufacturer, we are group company with over 24 years experiences.

2. How to buy your ideal products?

A: 30% deposit before producing, 70% balance before loading.

3.Q: What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 30 to 40 working days.

4.Q:How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

5.Q:How to install after the goods arriving destination?

A: We will provide detailed shop drawings to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

Write Us

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're

creatingwould like to partner up or just say hi!